Family Truckster Vol. 2

- Thread starter LBarr2002

- Start date

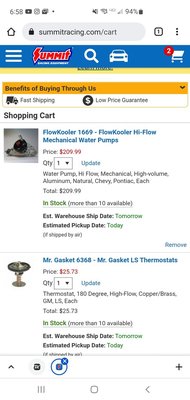

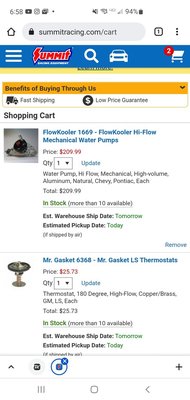

I drove the jeep up to OSCAR this year and Burgundy brought the truck and trailer up Friday after the kids got out of school. Saturday morning I noticed a puddle/stain in the gravel that didn't dry up. There was an active drip from the water pump weep hole. After consulting a few experts, I decided to top it off and drive it home rather than change it in the campground. We got home with no issues, so I'll be able to go ahead and upgrade instead of buying whatever was on the parts store shelf.

I'm running this same combo on the jeep and it made a noticeable difference with the low rpm lugging around. I haven't had any cooling issues with the truck and don't expect to, but this can't hurt. It turns really low rpm when converter locked up in OD and will flow more coolant at idle.

I'm running this same combo on the jeep and it made a noticeable difference with the low rpm lugging around. I haven't had any cooling issues with the truck and don't expect to, but this can't hurt. It turns really low rpm when converter locked up in OD and will flow more coolant at idle.

I am going to be doing some cooling upgrades to the CJ soon because I’d like to add air to it eventually. My plan was to start at a radiator upgrade but I think I’ll do this as well.

We ran it pretty hard up the trails this weekend and it never over heated but it was a little warmer than I like. I like some room for error when you’re hammering on them.

We ran it pretty hard up the trails this weekend and it never over heated but it was a little warmer than I like. I like some room for error when you’re hammering on them.

Since we bought this thing the air hasn't been really cold on the passenger side. I've done the hvac door relearn procedure before and it would get better for a while. We hadn't driven it in 2 months but yesterday we drove it to Sandhills and it was warm on passenger side, and one of the vent flaps wouldn't move to shut off the warm air. When we got home I did the relearn again and it stuck itself on full melt your face off heat. So, couldn't put off blend door actuator any longer.

Of course the passenger temp control is the hardest one to get to, on top of the heater box under the dash. I've watched a bunch of YouTube videos before, and last night, and decided to do the through the air bag hole method. I've read all the horror stories and 4-6 hours, etc. It took me 2 hours to get the old one out (including making the custom tool) and 30 minutes to put it back together after a run to the parts store. The actuator was $31 and in stock at Oriellys.

I won't recap the YouTube videos, but a couple observations. This being a quadrasteer, rear entertainment, fully loaded model, there was a harness attached to the crash bar that I didn't see in any of the videos. It's in the way but you can pull the Christmas tree retainer and move it out of the way enough. Also, I removed the dash panel where the quadrasteer button is. I didn't see that in the videos, but it gives you another access point and lets you actually see the left screw instead of doing it blind.

The screws are 7/32 and the midget wrench below worked perfectly for the right side screw. The left one is down behind the actuator where a flat wrench can't get on it, but a 7/32 socket and ratched doesn't have the overhead clearance to get in there. Enter the welder.

I took an old 1/4" drive "breaker bar" from a tool set my Granddad bought me from a yard sale when I was probably 6-8. Also took a 7/32 12 point socket from another tool set I have from my other Granddad. (It's important to use a 12 point because its very hard to get the range to turn it). I welded the socket on and tried it, but the handle was too short. I roughly measured how long the handle needed to be, and 6.5" is the ideal length. Long enough to reach across the actuator but not too long that it hits other things trying to turn. A piece of 1/4" square tacked on worked great.

Now the wife will be comfy on the camping trip next weekend.

Back to that vent that wouldn't close.... What happens when your wife tries to free it up and breaks it? You go out back to your Denali parts truck and grab some more.

Last edited:

one of the biggest things i do not miss about my Yukon. The HVAC system and its damn quirks. ARGH!!!

Over the past few months I didn't drive it often, but when I did it was trips. To Bristol unloaded for Cleetus' Bristol 1000 (see above) then to NC camping, and Windrock coming up. On cold start there has been an occasional rattle. I was originally thinking the starter was sticking, but over the NC weekend it did it a few times and we were thinking something in the exhaust. Monday I started it cold and got under it and it was definitely coming from bell housing. Irregular tick for a few seconds then goes away. I was starting to think cracked flex plate.

I called my transmission guy to get his opinion and he said bring it out and I'll check it in the morning. It was the starter gear not retracting and bouncing against the flex plate. He replaced it, pulled the inspection cover to check the flex plate, and said it looked good. It's also been slow to start since I got it. Sounds like new now.

I called my transmission guy to get his opinion and he said bring it out and I'll check it in the morning. It was the starter gear not retracting and bouncing against the flex plate. He replaced it, pulled the inspection cover to check the flex plate, and said it looked good. It's also been slow to start since I got it. Sounds like new now.

Looks like the Family Truckster 2.0 is jeep duck approved... Congratulations on your first duck larry!

View attachment 23149

View attachment 23150

View attachment 23149

View attachment 23150

Coming back from the St Augustine camping trip it flashed the service 4wd message and has done it a few times since. It also wouldn't shift to low range. While the transmission guy had it for the starter issue, I asked him to check the tcase error. He said it was the shift motor but they are discontinued from GM so couldn't get one on short notice.

I ordered the Dorman one from Amazon and a new gasket and put it in tonight. All fixed, but...

The new motor did not fit that alignment bushing in the top hole. I put it together without but now I'm second guessing myself. Should I pull it back out and drill the motor to fit the bushing?

I ordered the Dorman one from Amazon and a new gasket and put it in tonight. All fixed, but...

The new motor did not fit that alignment bushing in the top hole. I put it together without but now I'm second guessing myself. Should I pull it back out and drill the motor to fit the bushing?

is there a different version? why would it not fit? maybe check the part number?

The Dorman is the "good" one. There are cheaper ones on Amazon.